A TRUSTED PARTNER TO THE SEMICONDUCTOR INDUSTRY

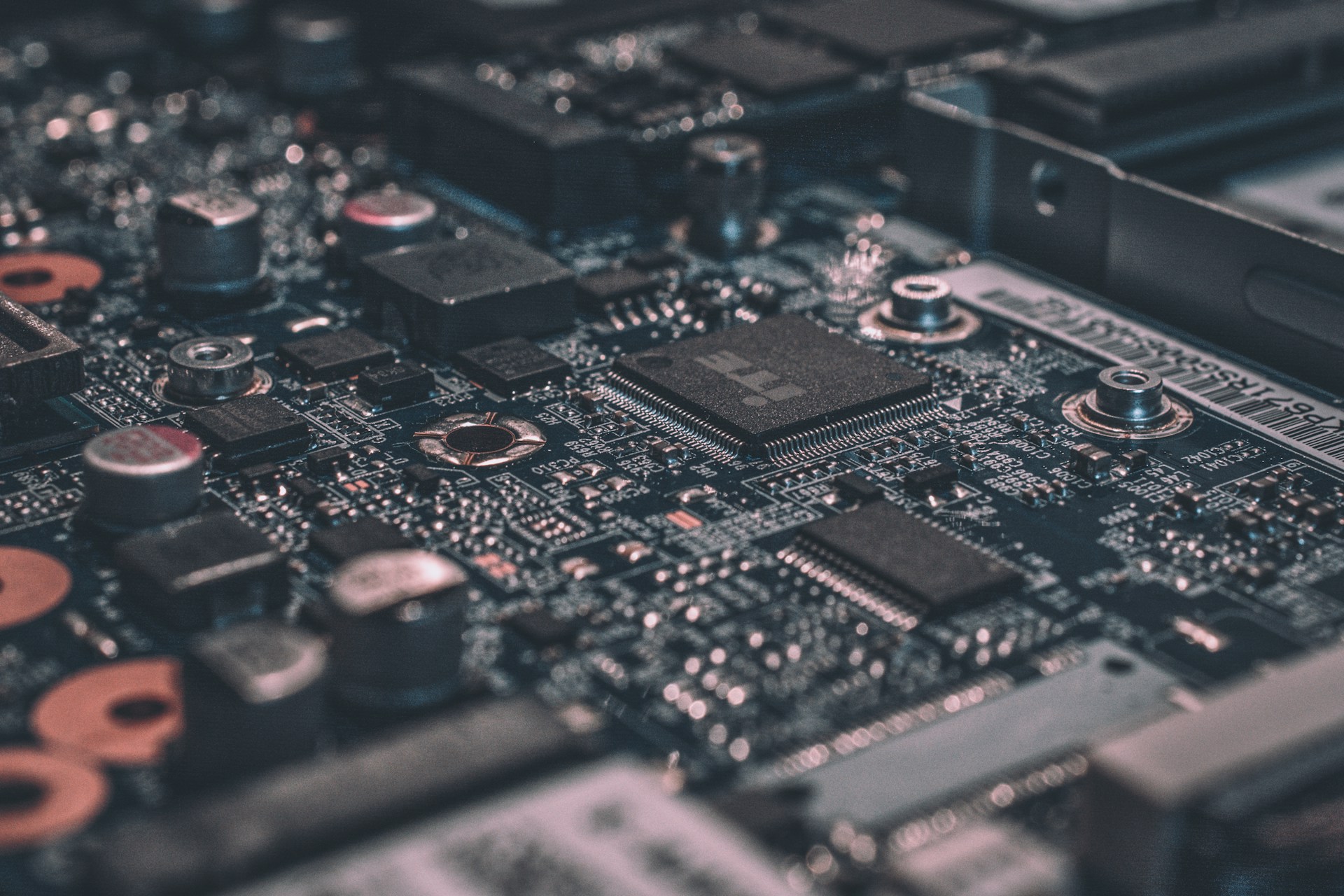

Membrane Systems for Microelectronics & Semiconductor Industry

The semiconductor industry, a major contributor to the global economy, has a high demand for water. The production of a single 8-inch silicon wafer, which is used to make approximately 100 chips, can require up to 7,500 liters of water, with about two-thirds of that being ultrapure water. Ultrapure water is essential as it serves as an industrial solvent and is purified to the highest standards to eliminate all types of contaminants, including organic and inorganic compounds, dissolved and particulate matter, and dissolved gases.

As the largest consumer of ultrapure water, the semiconductor industry is faced with significant water challenges. It not only requires large volumes of water at a high standard but also generates a substantial amount of wastewater that must meet specific disposal or reuse standards.

To address these challenges and mitigate the impact on local water sources and the environment, as well as reduce production costs, the industry must prioritize water reduction, reuse, and recycling efforts.

Key Applications:

Memtik offers a variety of ultrafiltration (UF) and reverse osmosis (RO) technologies designed specifically for the pretreatment phase in the production of ultrapure water (UPW).

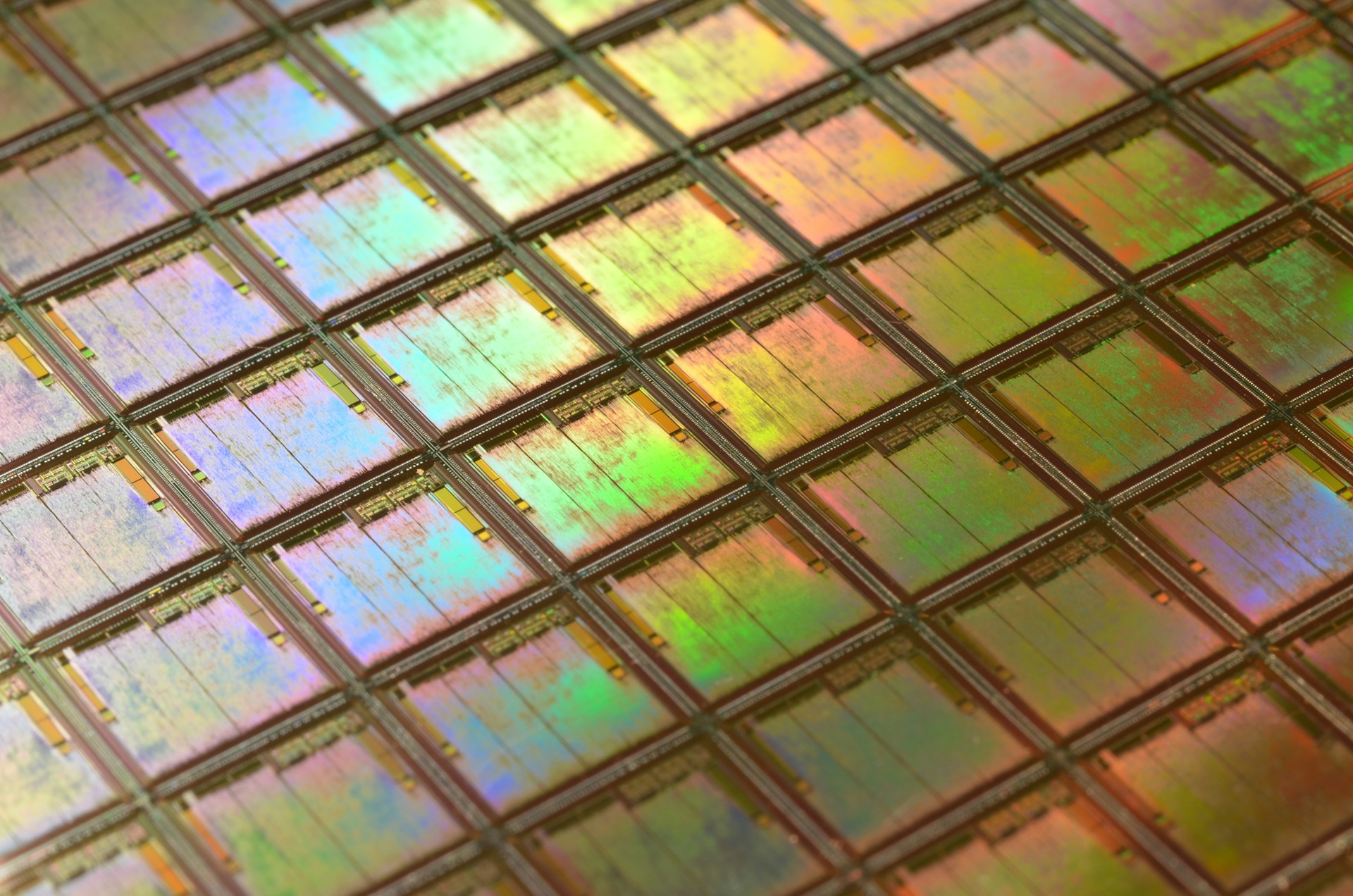

In the semiconductor industry, ultrapure water (UPW) is crucial for cleaning and rinsing silicon wafers, which are used in chips and photovoltaic cells. The size of the wafer and the quality of water are directly related, with smaller wafers requiring higher water quality. Even trace impurities in UPW can result in reduced yield and defects in the wafer. As wafer sizes continue to shrink, the removal of trace impurities, particularly silica, becomes increasingly important.

Silica can exist in water in various forms, including dissolved, colloidal, or granular. Impurities that remain on the wafer surface after the water evaporates can cause damage, with silica potentially creating unwanted connections between conducting surfaces. Industry requirements dictate that the level of silica (SiO2) in UPW must not exceed 0.3 ppb.

The semiconductor industry's significant water consumption also results in the generation of large volumes of wastewater. Regulatory bodies closely monitor water consumption and the quality of discharged water to mitigate the potential for aquatic pollution.

Some Membrane Usage Example:

UF – Pre-RO treatment

RO – Ultrapure water production & recycle

Our Capabilty & Strength

Ultrapure

Nowhere is quality and precision more important than with those applications that require ultrapure water. With a dedication to research and a commitment to current good manufacturing practices (cGMP), Memtik offers a wide range of solutions, from individual pieces of equipment to complete integrated plants, by integrating a broad array of state-of-the-art technologies.

Our expanded staff of knowledgeable experts is always willing to help with equipment selection, specification, and design.

Common Applications

USP

CLSI

ASTM

SEMI

WFI

Our Products and Services Include

Media Filtration

MF/UF

NF/RO

Demineralizers

Ozone Solutions

TOC Reduction Systems

Endotoxin/Pyrogen Removal

Ultraviolet Disinfection Solutions

Process Control/Automation Solutions

PP/PVDF/LXT/Stainless Piping Systems

Electrodeionization

On-line Analytical Instruments

Remote Monitoring

Validation/cGMP Compliance

Upgrades & Retrofits

Process Evaluation & Optimization Services

Aftermarket Parts

Process Water

In-Process Filtration

Wastewater Treatment